Drawing Thread Callout

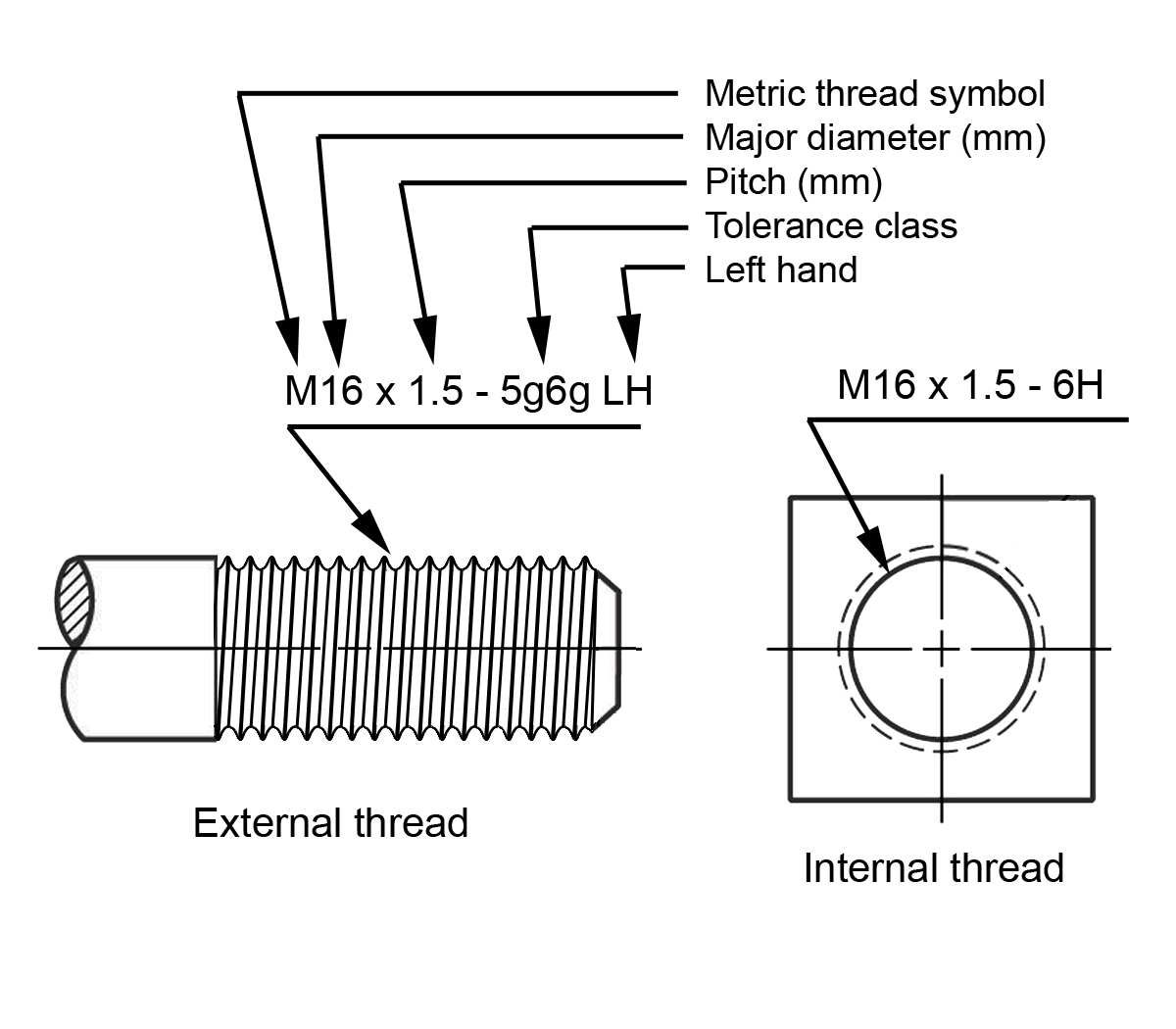

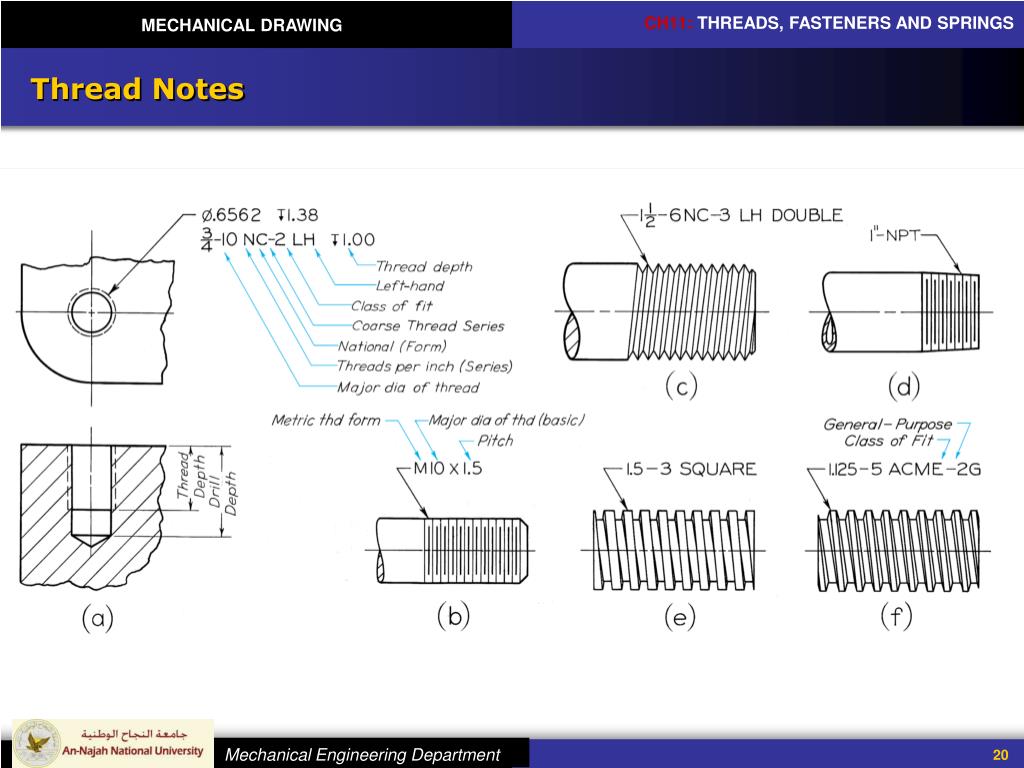

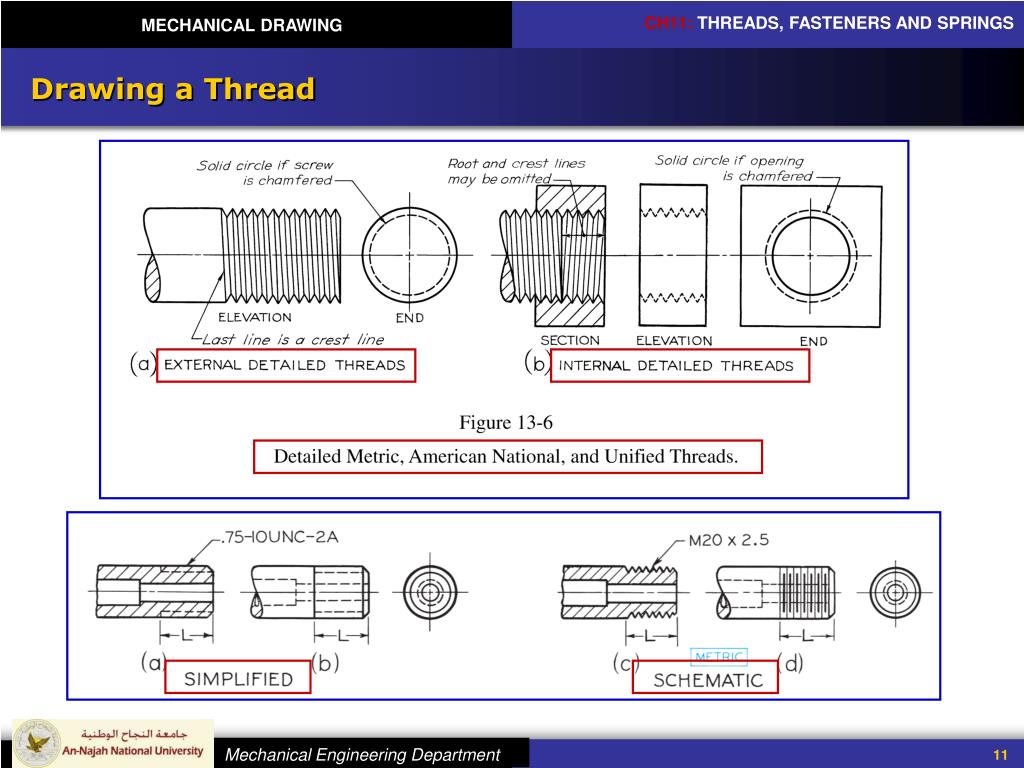

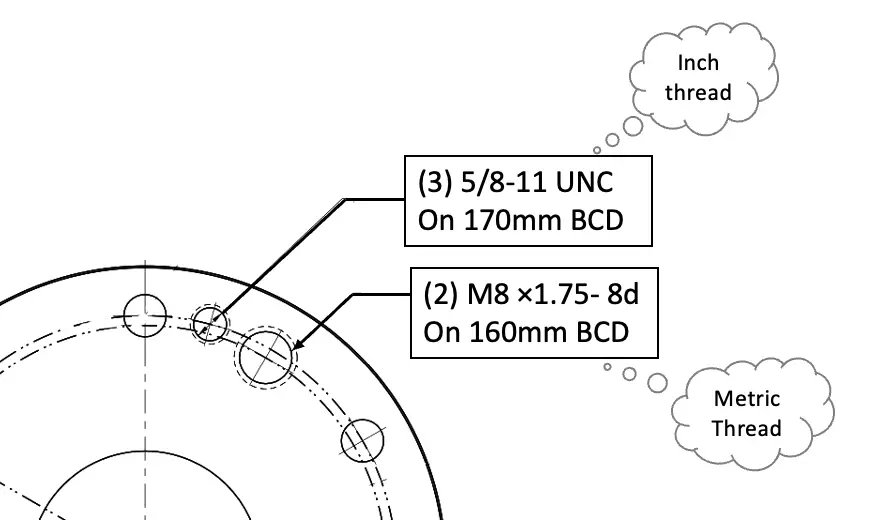

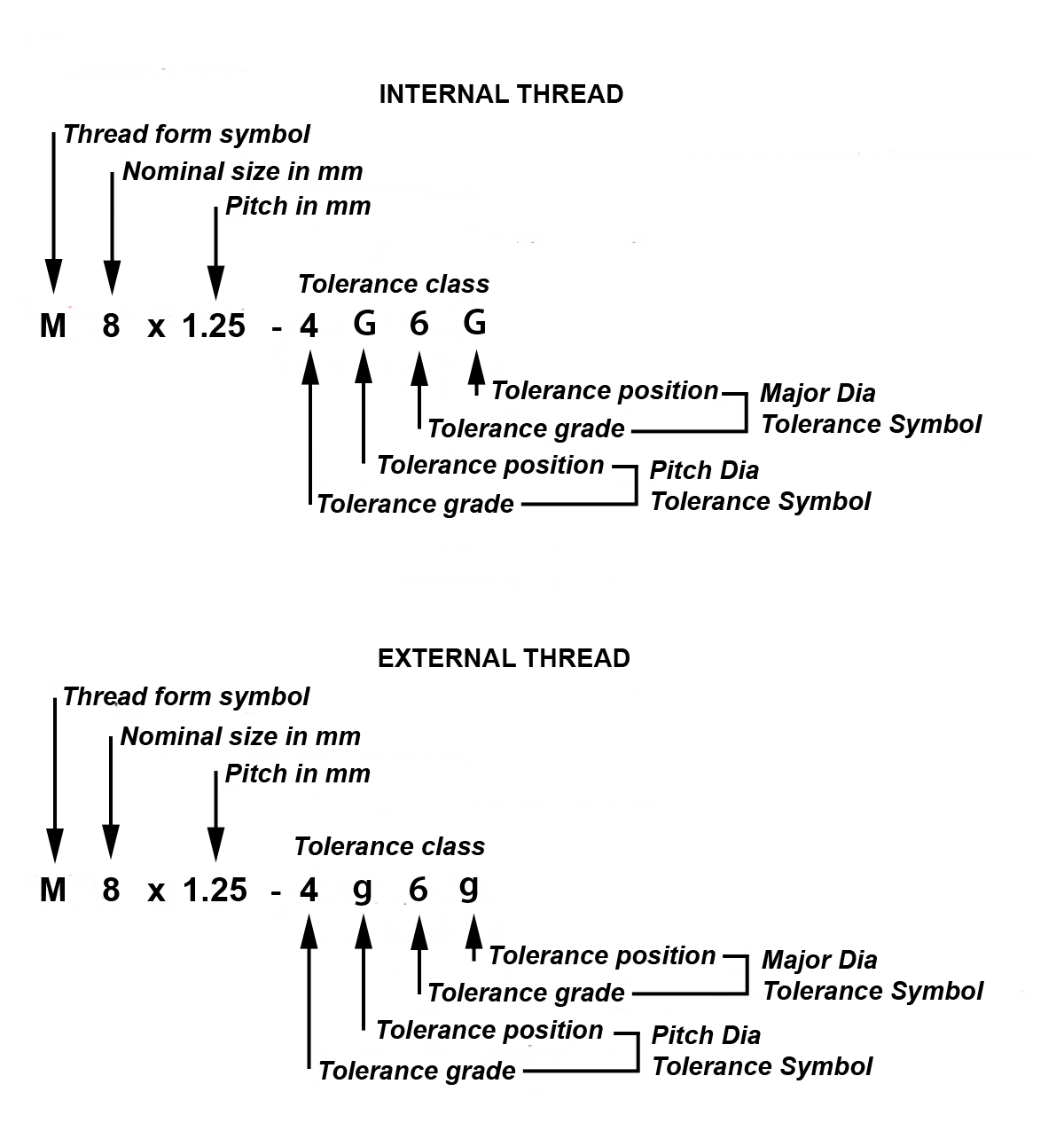

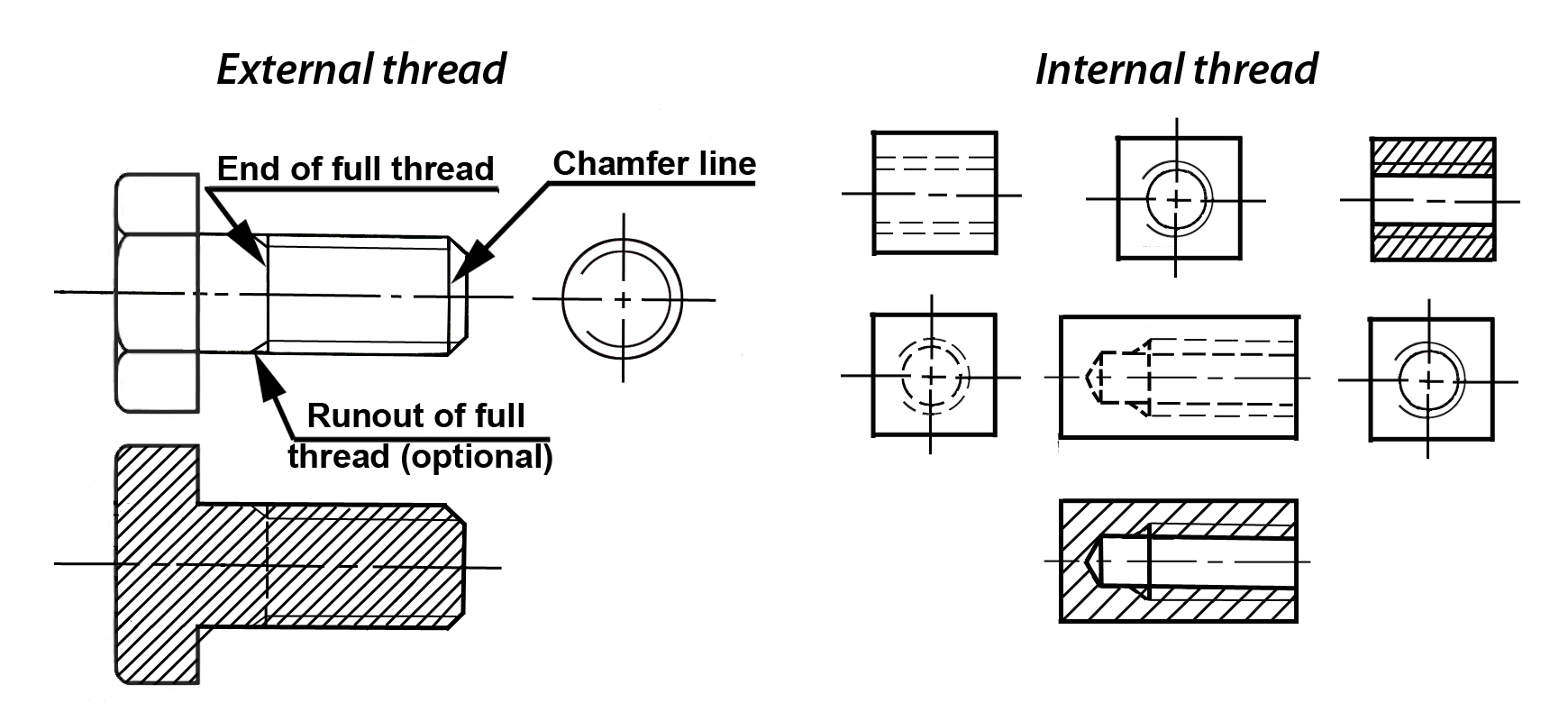

Drawing Thread Callout - Start by creating a new drawing in solidworks and insert the desired view of your part or assembly. Steps creating a hole or thread callout: Web a cosmetic thread represents the minor (inner) diameter of a thread on a boss or the major (outer) diameter of a thread on a hole and can include a hole callout in drawings. Web apply a hole callout to a hole or thread, automatically inserting the metadata of the hole or thread. Web some examples include thread specifications, surface finishes, surface quality, and dimension tolerances. It will also define the standard methods of specifying threads and all of. Inch thread and metric thread callout on the engineering drawing. Web use the hole/thread callout tool in a drawing to add a callout to an external thread feature. Web follow the steps below: This method is widely used for materials such as. The thread callout is defined in the cosmetic thread feature of the source part or. Web follow the steps below: This method is widely used for materials such as. Start by creating a new drawing in solidworks and insert the desired view of your part or assembly. December 2020 edited december 2020 in community support. If the cosmetic thread pertains to a hole, use hole callout from the commandmanager. This will display the relevant information for the hole. Steps creating a hole or thread callout: Web in drawings, you can add cosmetic thread callouts to external cosmetic threads. Web the smart dimension tool creates a simple thread callout when you select the cosmetic thread of. Web use the hole/thread callout tool in a drawing to add a callout to an external thread feature. In the above tap hole callout, we have given two callouts to understand it in both metric. This handout will focus on the standards of annotation for. Web how do i apply a callout for a threaded fastener, in a drawing. This. December 2020 edited december 2020 in community support. Web the difference is one group says also call out diameter of the hole to be drilled to prepare for tapping, second group says don't include diameter of the hole, the. Web the smart dimension tool creates a simple thread callout when you select the cosmetic thread of a threaded hole. We. Web apply a hole callout to a hole or thread, automatically inserting the metadata of the hole or thread. December 2020 edited december 2020 in community support. Web how do i apply a callout for a threaded fastener, in a drawing. Inch thread and metric thread callout on the engineering drawing. This method is widely used for materials such as. Inch thread and metric thread callout on the engineering drawing. Web in drawings, you can add cosmetic thread callouts to external cosmetic threads. Start by creating a new drawing in solidworks and insert the desired view of your part or assembly. This method is widely used for materials such as. In the above tap hole callout, we have given two. In the above tap hole callout, we have given two callouts to understand it in both metric. Web how do i apply a callout for a threaded fastener, in a drawing. This method is widely used for materials such as. Look for a label with the callout printed on it. We can visualize each hole’s tolerance zone as a cylinder. In the above tap hole callout, we have given two callouts to understand it in both metric. December 2020 edited december 2020 in community support. It is usually not printed on the screw. Web a cosmetic thread represents the minor (inner) diameter of a thread on a boss or the major (outer) diameter of a thread on a hole and. It is usually not printed on the screw. Web use the hole/thread callout tool in a drawing to add a callout to an external thread feature. Drilling and tapping is one of the most common and traditional methods for creating threaded holes. Web in drawings, you can add cosmetic thread callouts to external cosmetic threads. Web apply a hole callout. Steps creating a hole or thread callout: This will display the relevant information for the hole. We can visualize each hole’s tolerance zone as a cylinder with a diameter of ø.016 inches, having an axis perfectly. Web a cosmetic thread represents the minor (inner) diameter of a thread on a boss or the major (outer) diameter of a thread on. Web follow the steps below: We can visualize each hole’s tolerance zone as a cylinder with a diameter of ø.016 inches, having an axis perfectly. This method is widely used for materials such as. You can find the tool on the drawings toolbar : This will display the relevant information for the hole. Inch thread and metric thread callout on the engineering drawing. Web in drawings, you can add cosmetic thread callouts to external cosmetic threads. It is usually not printed on the screw. Web some examples include thread specifications, surface finishes, surface quality, and dimension tolerances. Steps creating a hole or thread callout: Start by creating a new drawing in solidworks and insert the desired view of your part or assembly. This handout will focus on the standards of annotation for. The thread callout is defined in the cosmetic thread feature of the source part or. Drilling and tapping is one of the most common and traditional methods for creating threaded holes. Look for a label with the callout printed on it. In the above tap hole callout, we have given two callouts to understand it in both metric.

Dimensioning threaded fasteners Engineering Design McGill University

PPT MECHANICAL DRAWING Chapter 11 Threads Fasteners and Springs

How to Draw Threaded Hole in Autocad 2d Adkins Fricaunt

PPT MECHANICAL DRAWING Chapter 11 Threads Fasteners and Springs

Thread Drawing

How to Read Screw Thread Designation? ExtruDesign (2022)

Dimensioning threaded fasteners Engineering Design McGill University

PPT Threads and Fasteners PowerPoint Presentation, free download ID

Dimensioning threaded fasteners Engineering Design McGill University

Dimensioning threaded fasteners Engineering Design McGill University

December 2020 Edited December 2020 In Community Support.

Web Apply A Hole Callout To A Hole Or Thread, Automatically Inserting The Metadata Of The Hole Or Thread.

It Will Also Define The Standard Methods Of Specifying Threads And All Of.

Web The Difference Is One Group Says Also Call Out Diameter Of The Hole To Be Drilled To Prepare For Tapping, Second Group Says Don't Include Diameter Of The Hole, The.

Related Post: