Mold Draw

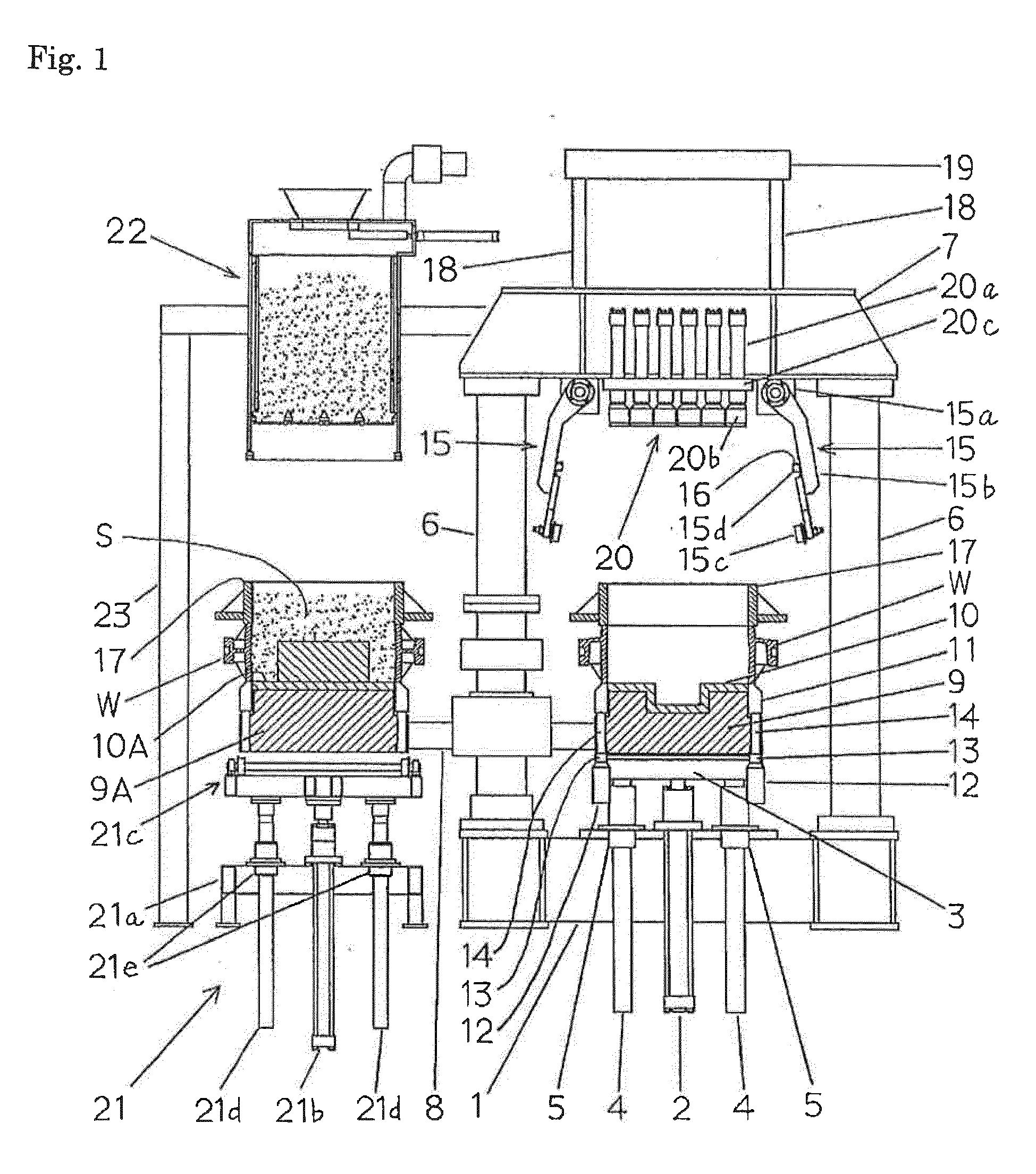

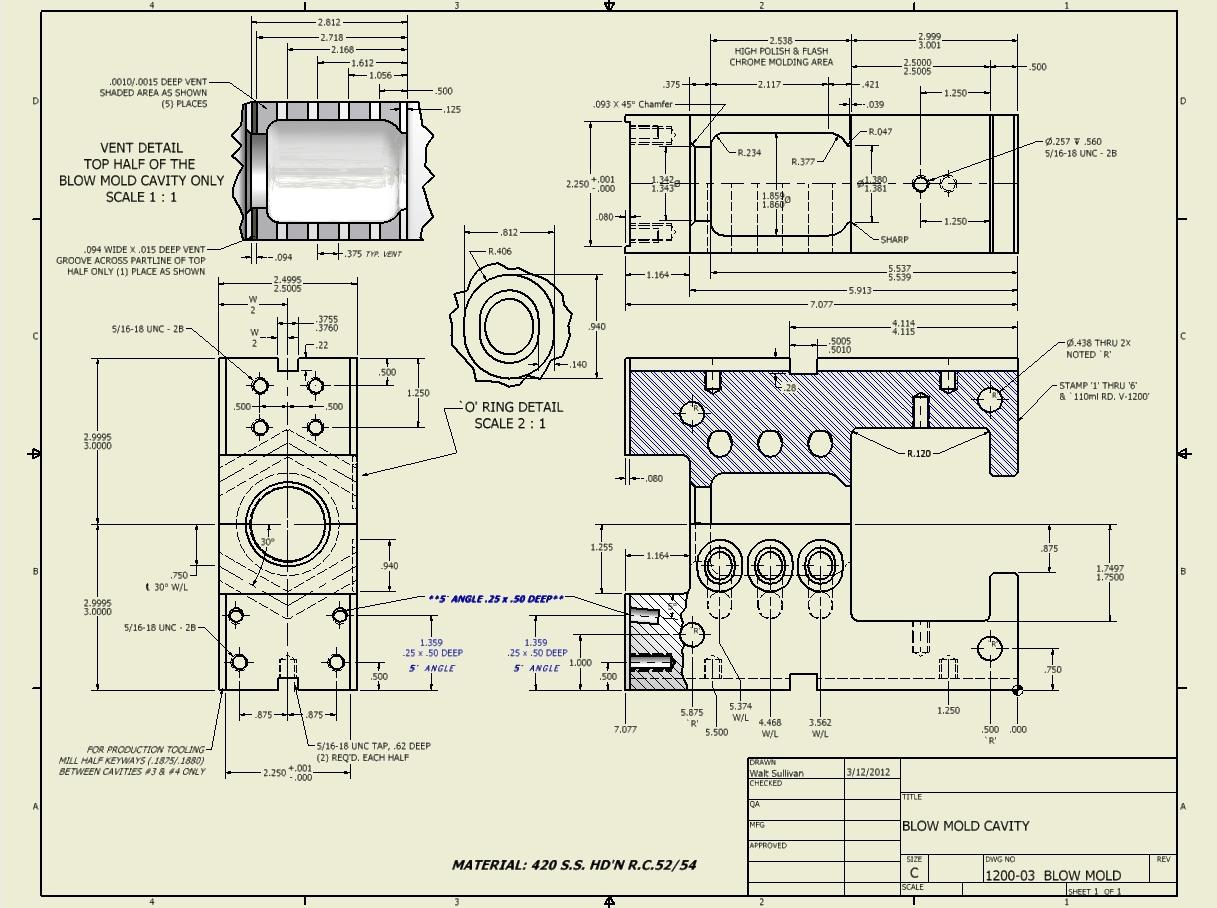

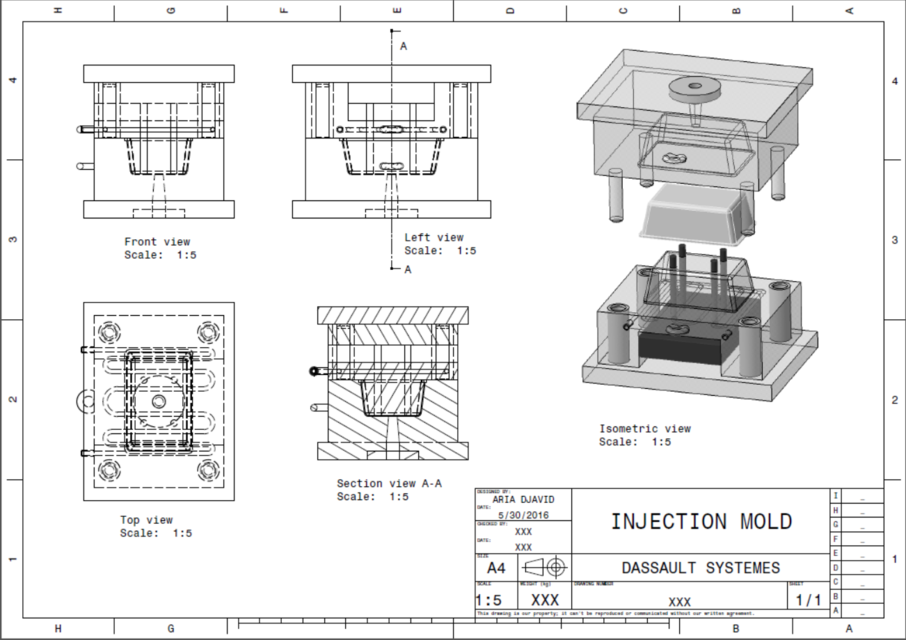

Mold Draw - Web you draw, and a neural network tries to guess what you’re drawing. (4) when evaluating individuals who. Remove the inserts from the dispenser drawer. Web process drawings are usually on mold assembly drawing. Slides, or sliders, release external undercuts, recesses or projections on a part’s outer surface that prevent the part’s direct removal from the mold cavity. It is also used for form. Line of draw the direction in which the two custom injection mold halves will separate from the plastic part allowing it to be ejected without any obstructions from metal creating undercuts. The multibody part file maintains your design intent in one convenient location. Web wasserman writes, alex sarr may check both boxes for top talent and best fit with the wizards. Start with cavity first, draw. A design branch showing the surfacing required to accomplish a proper mold split. Every plastic has a unique shrink rate. It is also used for form. To see this branch, follow this link. A draw ratio is the calculation that lets you know what gauge of plastic you need to start with for any given thermoformed part. Ribs refers to thin bladed features on a part that are used for strengthening wall sections. Potential knit lines • knit lines occur where to or mold melt fronts come together 1 to 2 degrees works very well in most situations. Defines the common steel types and their applications. Injection molding sliders and lifters are mechanisms that release a molded. Web mold design, how to draw blow mold jerry can 1 liter is manufacturing process for forming and joining together hollow plastic parts. Draw directions are a type of shape control. Spread features out more to allow plastic to stretch into recesses. The result of the tooling split is a multibody part containing separate bodies for the molded part, the. Web try reducing draw or adding fillets to your design. Msh is a hormone, called a regulatory neuropeptide, and it controls many other hormones, inflammation pathways, and basic defenses against invading microbes. Web draw ratio is a calculation that your thermoformer uses to determine the minimum thickness of the plastic sheet to produce your part. Remove the inserts from the. Ribs refers to thin bladed features on a part that are used for strengthening wall sections. 1 ratio as much as possible. Web we’re going to look at what to consider when selecting a parting line and what it means for part design. Web draw ratio is a calculation that your thermoformer uses to determine the minimum thickness of the. Remove the inserts from the dispenser drawer. (2) if specific allergic sensitivity is needed to allow immunotherapy to be initiated; It is also used for form. When designing the injection mold, consider the location of the gate as it can be placed in varying positions around the whole structure. Web try reducing draw or adding fillets to your design. Web wasserman writes, alex sarr may check both boxes for top talent and best fit with the wizards. This means that certain design elements such as a “t” shaped rib section cannot be “molded. Remove the detergent drawer by pressing the dispenser release button on the back of the detergent drawer and slide out. Potential knit lines • knit lines. Draw directions are a type of shape control. It is important to remember that the start of the thermoforming process is always a flat sheet of material. 0.5 degrees on all vertical faces is strongly advised. The location of the molding gate will affect the tolerances, the warpage, the surface finish. 1:1 draw ratio or less. The customer will specify the general steel types. Web wasserman writes, alex sarr may check both boxes for top talent and best fit with the wizards. The more stretching that occurs, the thinner the plastic gets. If you intend for a part to be manufactured by casting it or stamping it, the optimized shape must allow the two halves of. Web upmold rg series mold: 0.5 degrees on all vertical faces is strongly advised. Draw directions are a type of shape control. Web mold tools span from initial analysis to creating the tooling split. When drawinn final assembly drawing, use a 1: 1 to 2 degrees works very well in most situations. So far we have trained it on a few hundred concepts, and we hope to add more over time. Line of draw the direction in which the two custom injection mold halves will separate from the plastic part allowing it to be ejected without any obstructions from metal creating undercuts. It is also used for form. Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to a particular shape. This means increased susceptibility to mold illness, ongoing fatigue, pain, hormone abnormalities, mood swings, and much more. It divides the surface area of the mold by the footprint, or top surface, of the heated sheet. Web in mold illness, msh will be too low in over 95% of patients. Web process drawings are usually on mold assembly drawing. Spread features out more to allow plastic to stretch into recesses. (3) when testing individuals for agents that may potentially cause anaphylaxis; Web try reducing draw or adding fillets to your design. The location of the molding gate will affect the tolerances, the warpage, the surface finish. But the more you play with it, the more it will learn. When drawinn final assembly drawing, use a 1: Generally speaking, there should not be any surface of the part that is exactly 90 degrees to the line of draw on the mold.

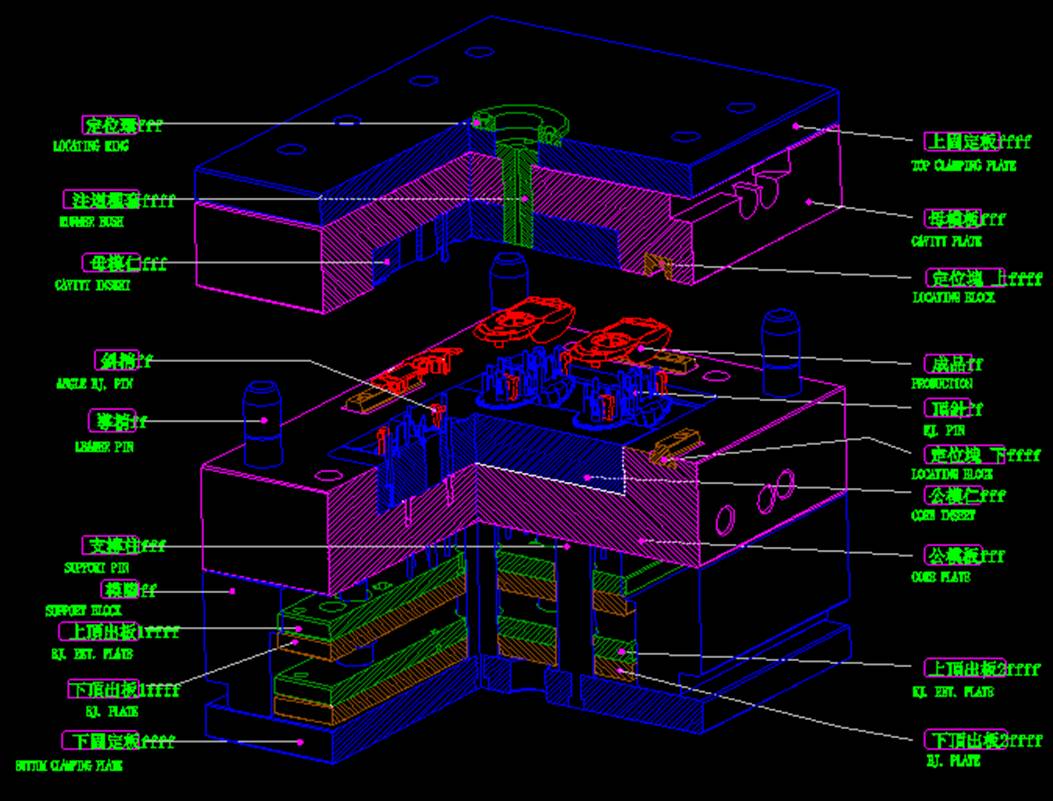

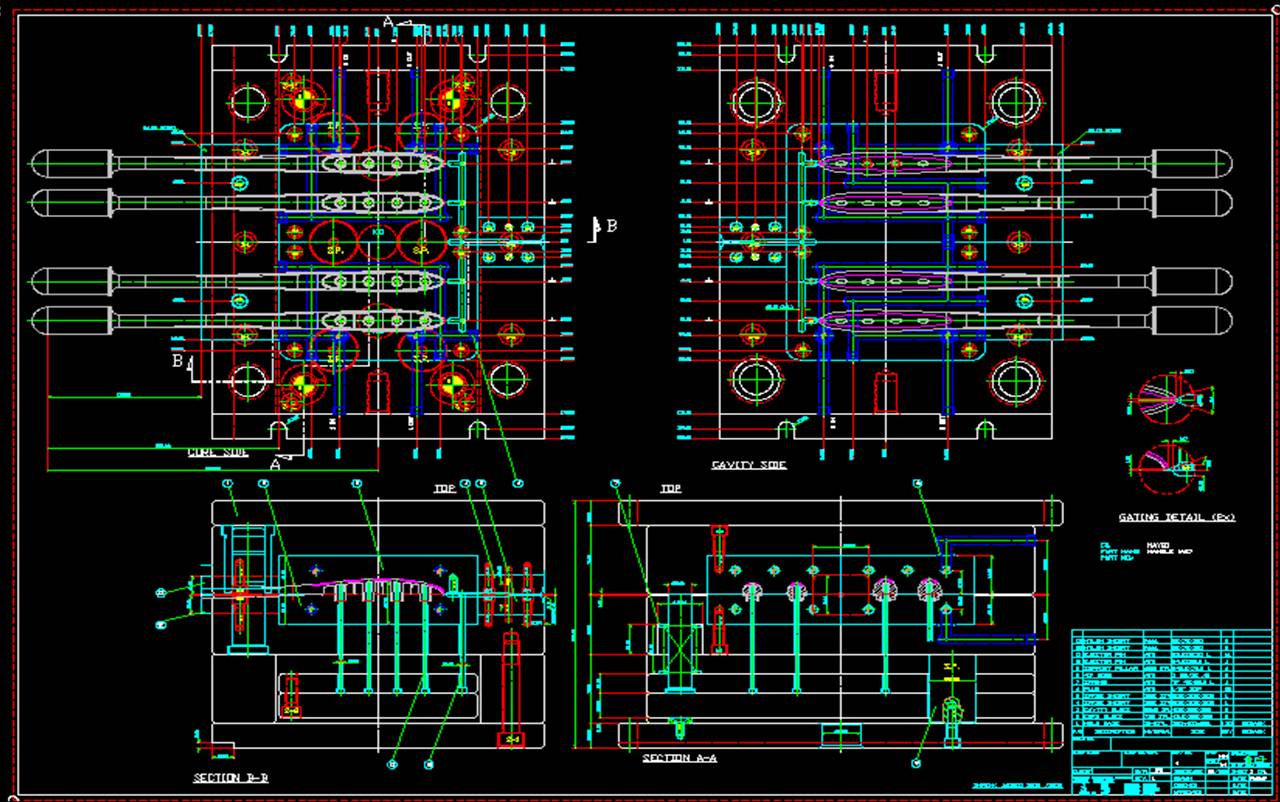

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at Explore collection of Mold Drawing

Mold Drawing at GetDrawings Free download

Mold product drawing design standards

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

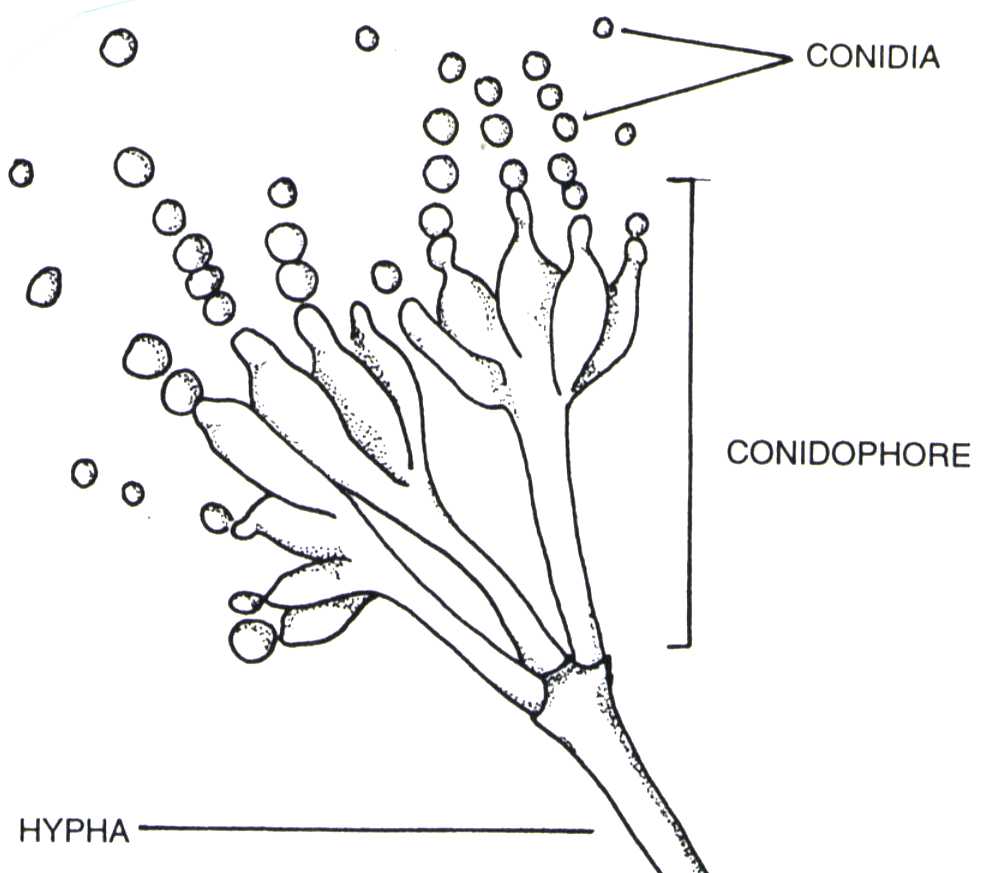

HOW TO DRAW MOLD LEARN TO DRAW DIFFERENT TYPES OF MOLDS YouTube

Mold Drawing at Explore collection of Mold Drawing

When Looking At A 3D Model Of A Part.

Web You Draw, And A Neural Network Tries To Guess What You’re Drawing.

Msh Is A Hormone, Called A Regulatory Neuropeptide, And It Controls Many Other Hormones, Inflammation Pathways, And Basic Defenses Against Invading Microbes.

Web Mold Tools Span From Initial Analysis To Creating The Tooling Split.

Related Post: